We deliver even the most difficult drawing parts in all materials. In addition to conventional and CNC turned, milled and long turned parts, our services also include stamping, bending and laser parts as well as cold and hot forming with multi-stage presses.

We fulfil all requirements outside the standard program:

- DIN-like parts: Standard and standard elements, adapted to the specific requirements of our customers

- Special fasteners: A new solution is developed according to the fastening situation Customer-specific drawing parts ...no matter whether turned, milled, punched, bent, pressed, cast, forged or welded

- Special materials for increased corrosion resistance, resistance to aggressive liquids and temperatures as well as for improving mechanical values

- Special surface treatments for securing screws and nuts with clamping and adhesive coatings, for increased protection of the surface against corrosion, for improved sliding and for a perfect appearance.

Cold formed parts:

Special screws, step bolts, internal threaded parts and sleeves for series production with large quantities

- Material: steel, stainless steel, aluminium, non-ferrous metals, special materials

Hot formed parts:

Bolts, structural parts, special screws and nuts with a high degree of forming or smaller quantities

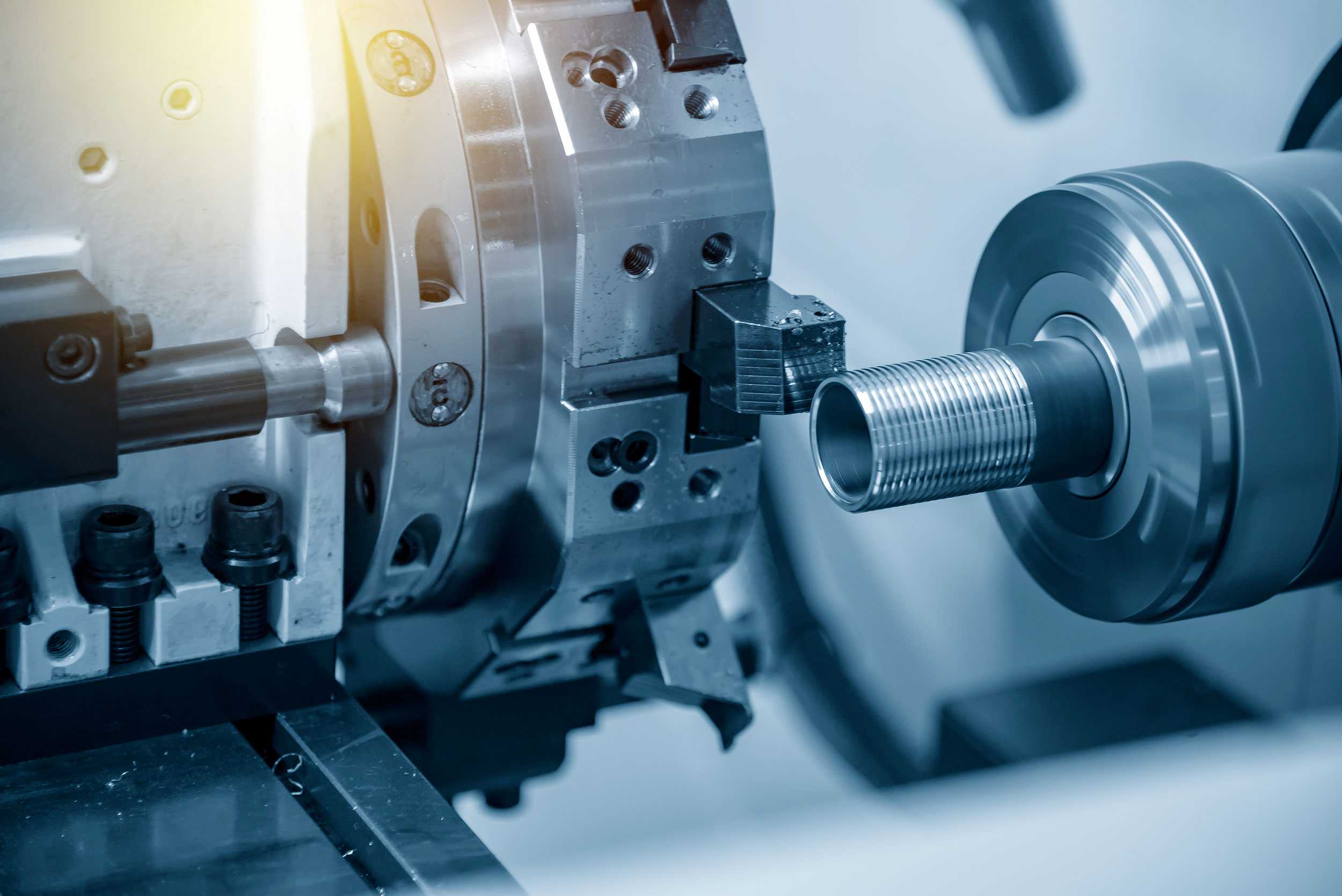

- Material: steel, stainless steel, special materialsPrecision turned parts:

Machined structural parts with or without without thread in smaller or larger quantities

- Material: steel, stainless steel, aluminium, non-ferrous metals, special materials

Punched and stamped-bent parts:

Construction and disc-like parts made of sheet metal or strip material

- Material: steel, stainless steel, aluminium, non-ferrous metals, special materials

In addition to standard fastenings such as hanger bolts, adjustable roof hooks made of stainless steel and aluminium, Profiness also offers special solutions on request.

Through close cooperation with our exclusive supply partners in all interesting procurement markets, we can offer you a constantly evolving product range in a wide range of alloys.

Quality awareness and modern communication technology are important criteria in the selection of our partners. A wide range of technical production possibilities in non-cutting and machining production, surface finishing and assembly enables us to supply you with both machined semi-finished products and ready-to-assemble products according to your specifications.